Vulcan Tool News

Vulcan Tool Company Earns ISO 9001:2015 & SDVOB Certification

Vulcan Tool Company Earns ISO 9001:2015 & SDVOB Certification Dayton, OH – March 10, 2025 – Vulcan Tool Company, operating under the legal entity Paradigm Industrial, is excited to announce its successful certification to the globally recognized ISO 9001:2015...

Vulcanaire: A Jig Grinding Alternative

In the world of precision machining, jig grinders have long been the go-to solution for achieving ultra-precise hole grinding and finishing. However, the high cost and specialized nature of these machines make them impractical for many shops. Fortunately, there is a...

Vulcan Tool Company is Now ThomasNet Verified!

Over 1,000 exhibitors present their innovations along the entire value chain at the No. 1 trade fair for the tube industry. Vulcan Tool Company provides tube cutting equipment to customers around the world.

Visit us at Tube Dusseldorf 2024!

Over 1,000 exhibitors present their innovations along the entire value chain at the No. 1 trade fair for the tube industry. Vulcan Tool Company provides tube cutting equipment to customers around the world.

We’re exhibiting at FABTECH 2023! Stop by booth D41838 to visit us!

Visit Vulcan Tool Company FABTECH ChicagoSeptember 11-14, 2023McCormick Place2301 S King DrChicago, Illinois www.fabtechexpo.com Learn about our Tube Cutting Machines and Shimmy Trim Dies for Deep Drawn Stampings Vulcan Tool Company...

Tube Cutting Machines Featured in Industry Journal

Vulcan Tube Cutting Machines Featured in The Tube & Pipe Journal: "Restoring Proven Tools For Future Success" This month The Fabricator's Tube and Pipe Journal wrote about how Vulcan Tool Company has provided H&H Tube a new Ringmaster and entered into a...

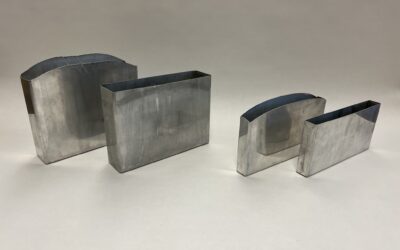

Trimming Prismatic & Cylindrical battery cell housings using a Shimmy Die

Prismatic battery cell housing is one of the latest innovations in battery technology. The Shimmy Die can trim an entire drawn part in one press stroke while controlling flatness and height.

Vulcan Tool Awarded Grant to Promote Manufacturing Explorer Post

$1,000 Grant Intended to Encourage Manufacturing Explorer Post Participation The Precision Metalforming Association Educational Foundation announced this week that Vulcan Tool Company has been awarded a grant through the foundation's Micro-Grant Program. The...

Vulcan Tool Visits Local High Schools

Promoting Open House and New Manufacturing Explorer Post Vulcan Tool Company President Ashley Webb visited local high schools recently to invite students to visit during the upcoming Open House event and promote the new Manufacturing Explorer Post. This past week he...

Manufacturing Day Open House

Community Open House at Vulcan Tool on Thursday, October 6th from 6pm-9pm This event is for anyone interested in manufacturing. All ages are welcome! During the open house visitors will have an opportunity to participate in hands-on activities. Come see what it is...